How federal trucking regulations shape liability in semi‑truck accident cases can be startling: studies show a large share of serious crashes involve clear safety violations that investigators can trace back to company practices.

The Federal Motor Carrier Safety Administration (FMCSA), created after the Motor Carrier Safety Improvement Act of 1999, was designed to reduce crashes, injuries, and deaths involving large commercial vehicles. Its regulations establish minimum standards for driver qualification, hours‑of‑service compliance, vehicle upkeep, cargo securement, and hazardous materials handling.

When a semi‑truck accident occurs, these standards provide a baseline duty of care. Attorneys and investigators rely on ELD logs, inspection reports, maintenance files, and the Drug and Alcohol Clearinghouse to reconstruct events and determine whether a motor carrier met its legal obligations.

This guide previews the federal rules that most influence fault and damages, showing how noncompliance can increase a company’s exposure after a wreck. For more detailed context, see Federal Trucking Laws That Impact Semi‑Truck Accident Claims.

Key Takeaways

- FMCSA rules set the baseline safety duties for carriers and drivers.

- Hours‑of‑service, ELDs, and maintenance records often decide liability in semi‑truck accident claims.

- Documented noncompliance can shift or increase company exposure.

- Investigators rely on logs, DVIRs, and the Clearinghouse to rebuild events.

- Understanding the interplay of federal standards and state law is crucial for successful claims.

Federal Trucking Regulations Today: Why They Matter in Semi‑Truck Accident Cases

Today’s federal safety framework sets minimum operating standards that shape how courts and investigators assign fault after a commercial vehicle crash. For background on the current regulatory framework, see FMCSA’s Rules and Regulations in Title 49 CFR.

The FMCSA publishes rules in Title 49 of the CFR that apply to employers, drivers, dispatchers, trainers, and managers who operate in interstate commerce. Those rules govern daily tasks — hours of service, inspections, maintenance, and cargo handling — so violations often provide clear, documented evidence of a breach of duty.

The agency also uses data tools such as the Safety Measurement System to flag higher‑risk carriers. Violations can result in fines, out‑of‑service orders, downgraded ratings, and heightened scrutiny.

Investigators link missing logs, incomplete inspection reports, or poor maintenance records to the sequence of events in a crash. That connection helps plaintiffs show how noncompliance increased the risk or severity of harm.

Early analysis of company practices and recordkeeping is essential. Prompt preservation demands and a review of a carrier’s safety history often shape settlement leverage and courtroom strategy. For a deeper look at how trucking crashes differ from other collisions, see Semi‑Truck Accident vs Car Accidents.

FMCSA and FMCSR: Origins, Purpose, and Role in Interstate Trucking

Since 2000, a dedicated safety administration inside the U.S. Department of Transportation has set and enforced rules that target high‑risk motor carriers. Its core mission is prevention: reducing crashes, injuries, and deaths by issuing minimum safety standards. For background on the agency’s mission and regulatory authority, see FMCSA’s About Us.

FMCSA Versus FMCSR: Roles Within the U.S. Department of Transportation

The FMCSA is the agency that writes and enforces policy. The FMCSRs are the codified rules found in Title 49 CFR. Think of the FMCSA as the regulator and FMCSR as the codebook. That split helps lawyers and investigators locate precise violations in semi‑truck accident claims.

Who Is Covered: Employers, Drivers, and Commercial Motor Vehicles Over 10,001 Pounds

Coverage extends to employers, dispatchers, mechanics, trainers, and drivers when operations affect interstate commerce. The scope includes any commercial motor vehicle with a gross vehicle weight rating or combination weight rating of 10,001 pounds or more.

- Hazmat vehicles that require placards are covered.

- Passenger vehicles with specific seat thresholds also qualify.

- Even occasional interstate trips can trigger FMCSR obligations.

Understanding this coverage is critical for victims and attorneys, since it defines which parties can be held accountable under federal law. For more on how vehicle classification impacts liability, see Commercial Vehicle Classes in Semi‑Truck Accident Cases.

How Federal Trucking Regulations Directly Impact Liability After a Semi‑Truck Accident

Clear breaches of safety law can move a case from disputed fault to a straight negligence claim. Lawyers first check whether a driver or company violated rules that were designed to prevent the exact harm that occurred. For background on how violations lead to enforcement and penalties, see FMCSA’s Civil Penalties and Settlement.

How Rule Violations Establish Negligence and Negligence Per Se

In many jurisdictions, a documented violation supports negligence per se. That means plaintiffs may avoid proving duty and breach and focus on causation and damages instead.

Key Regulations That Commonly Surface in Litigation

Commonly litigated areas include hours‑of‑service, ELD accuracy, driver qualification files, drug and alcohol testing, DVIRs, and maintenance records. These rules often reveal whether the carrier and driver met safety duties.

Using Regulatory Non‑Compliance to Link Causation and Damages

Attorneys map violations to crash mechanics — fatigue from excess hours, brake failure from missed inspections, or load shifts from poor securement. CSA BASICs and prior interventions can show a pattern of risk. For more on how courts assign responsibility when violations surface, see Employer vs Driver Liability in Semi‑Truck Accidents.

| Rule Area | Typical Evidence | Crash Mechanism | Impact On Liability |

|---|---|---|---|

| Hours of Service / ELDs | Logs, ELD downloads | Driver fatigue | Supports causation; increases damages |

| Maintenance / DVIRs | Inspection reports, repair orders | Brake or tire failure | Shows mechanical negligence by company |

| Driver Qualification / Testing | CDL files, Clearinghouse entries | Unfit or impaired operation | May establish foreseeability and employer fault |

Hours‑of‑Service Rules and ELD Compliance: Fatigue, Evidence, and Enforcement in Semi‑Truck Accident Claims

Limits on daily and weekly work time exist to reduce fatigue‑related harm and to create verifiable evidence after an incident. These rules create a clear timeline for investigators and courts to test whether a driver exceeded safe limits. For background on current hours‑of‑service regulations, see FMCSA’s Hours of Service Rules.

The 11‑Hour Driving Limit and 14‑Hour On‑Duty Window

Under current HOS rules, a driver may drive up to 11 hours within a 14‑hour on‑duty window after at least 10 consecutive hours off. That structure lets experts reconstruct an exact workday and spot overages.

Mandatory 30‑Minute Breaks, 10‑Hour Off‑Duty, and the 60/70‑Hour Limit

Drivers must take a 30‑minute break after eight hours of driving. Weekly caps limit drivers to 60 or 70 hours over seven or eight days, with a 34‑hour restart available. These checkpoints—daily caps, breaks, and weekly limits—offer multiple moments where non‑compliance can be tied to fatigue in a semi‑truck accident claim.

Electronic Logging Devices: Data Integrity, Admissibility, and Disputes

ELDs connect to the vehicle engine and record movement automatically, replacing paper logs. That engine‑synced data can be matched to dispatch notes, toll records, and weigh‑station timestamps to test log integrity. Discrepancies between ELD data and other records often become pivotal evidence in semi‑truck accident litigation. For more on how fatigue and log violations shape liability, see Hours‑of‑Service Violations in Semi‑Truck Accidents.

| Aspect | Evidence Type | Common Disputes |

|---|---|---|

| Daily Limits | ELD downloads, log edits | Unidentified drive time; improper duty status |

| Breaks & Restarts | Duty status changes, timestamps | Misapplied exemptions; compressed rest periods |

| Enforcement Impact | Out-of-service orders, CSA scores | Whether carrier supervision proved adequate |

In lawsuits, experts cross-reference ELD outputs with the HOS framework to determine causation. Enforcement records and ELD data often show whether a carrier enforced compliance or allowed routine overages.

Driver Qualification, CDL Standards, and Drug & Alcohol Testing in Semi‑Truck Accident Cases

Licensing, medical fitness, and testing rules determine whether a driver was legally eligible to operate at the time of a crash. Investigators pull qualification files first because they show credentialing, medical cards, and prior safety history. For background on driver qualification and medical certification requirements, see FMCSA’s Driver Qualification File Checklist.

CDL, Age, Medical Certification, and Driver Fitness Files

To operate a CMV, a commercial driver license is required and interstate drivers typically must be 21. A driver must hold valid medical certification from FMCSA‑approved examiners. Employers must keep driver qualification files that include MVRs, employment checks, and prior accidents. Those files often become critical evidence when a company’s compliance is questioned in semi‑truck accident cases.

Drug and Alcohol Testing, the Clearinghouse, and Return‑to‑Duty Implications

Drug and alcohol testing covers pre‑employment, random, post‑accident, reasonable suspicion, return‑to‑duty, and follow‑ups. The Clearinghouse records violations and, since 2024, state agencies may downgrade a driver license until return‑to‑duty steps are complete. Drivers must pass FMCSA‑compliant medical exams and testing to remain on safety‑sensitive duties. A commercial driver who fails or refuses testing is removed from operation, and the company can face increased liability.

For more on how drug and alcohol violations affect liability and recovery, see Bad Faith Insurance Tactics in Semi‑Truck Accident Claims.

Vehicle Maintenance, DVIRs, and Inspections: Proving Mechanical Negligence in Semi‑Truck Accidents

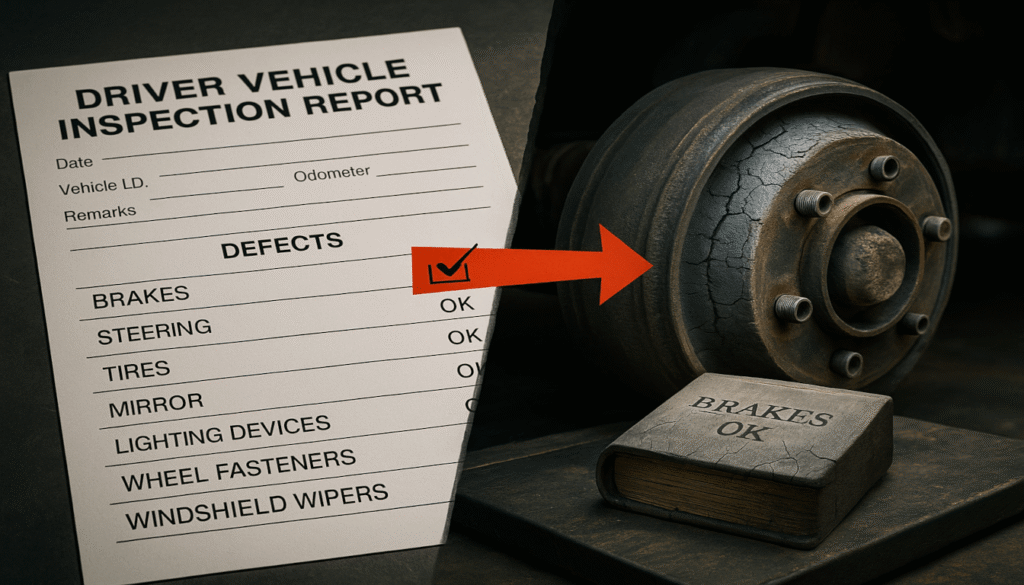

Post‑crash litigation frequently turns on whether routine service was performed and documented. Inspectors and lawyers look first at pre‑ and post‑trip DVIRs, annual certificates, and repair orders to map mechanical cause and blame. For background on inspection and DVIR requirements, see FMCSA DVIR requirements.

Daily and Annual Inspections, Out‑of‑Service Orders, and Repair Proof

Drivers complete DVIRs before and after trips. Those reports flag defects that must get prompt service with signed repair proof before the vehicle returns to the road.

Annual inspections require qualified personnel and retained certificates. Missing or stale inspection documents often support claims of negligent vehicle maintenance by the company or carrier.

Out‑of‑service orders show immediate risk. The 2024 CVSA Roadcheck placed 9,345 vehicles out of service — a statistic that regularly appears in mechanical‑failure cases.

Maintenance and Repair Records: Preservation, Spoliation, and Case Strategy

Mechanical‑failure allegations hinge on parts histories, technician sign‑offs, and shop work orders. Gaps or inconsistent entries can be powerful evidence of non‑compliance with rules and service protocols.

Attorneys issue preservation letters early to prevent spoliation of DVIRs, telematics, and maintenance files. In court, authenticated maintenance documentation often decides whether a truck was safe to operate. For more on how evidence preservation strengthens liability claims, see Preserving Evidence in Semi‑Truck Accident Cases.

Cargo Securement, Hazardous Materials, and Weight Compliance: Evidence in Semi‑Truck Accident Litigation

When a trailer’s load shifts, stopping distance and steering response can change in seconds. That sudden shift explains why securement and weight rules matter to both safety and liability. For background on federal cargo securement standards, see FMCSA’s Cargo Securement Rules.

Tie‑Downs, Load Shifts, and Open‑Trailer Requirements

Proper tie‑downs must match the cargo’s weight and working load limits. Chocks and wedges prevent rolling and reduce shift risk.

Open trailers require extra containment to stop debris ejection and protect other road users. Failure to follow these rules often appears in reconstruction as the initiating cause of loss of control.

Hazardous Materials Registration, Labeling, Training, and Penalties

Transporting hazardous goods demands registration, correct classification, intact packaging, and clear labeling. Employers must document employee training. Non‑compliance can trigger steep civil fines and criminal exposure and dramatically raise company liability after a crash.

Gross Vehicle Weight and Axle Limits: Braking Distance, Stability, and Road Safety

Overweight or poorly distributed loads harm braking performance and increase rollover risk. Weigh‑station tickets, bills of lading, and scale records are key evidence to show whether the gross vehicle exceeded limits at the time of the incident.

| Area | Typical Proof | Safety Effect | Legal Impact |

|---|---|---|---|

| Securement | Tie‑down counts, inspection checks | Prevents load shift and loss of control | Supports or rebuts negligent loading claims |

| Hazmat | Registration, training records, labels | Reduces spill and exposure risk | Violations carry civil and criminal penalties |

| Weight | Scale tickets, BOL, axle records | Affects braking and stability | Overweight evidence raises carrier responsibility |

For more on how company training failures increase liability, see Negligent Hiring and Training in Semi‑Truck Accidents.

CSA Scores and FMCSA Enforcement Actions: Measuring Safety in Semi‑Truck Accident Cases

CSA scores turn complex safety data into clear signals that reveal a carrier’s real‑world risk. The program ranks carriers across seven BASICs: Unsafe Driving, Crash Indicator, HOS Compliance, Vehicle Maintenance, Controlled Substances/Alcohol, Hazardous Materials, and Driver Fitness. For background on how CSA works and what the scores mean, see FMCSA’s CSA Program Factsheet.

The percentile system creates a number‑based snapshot that regulators, insurers, and plaintiffs use to judge carrier safety performance. Lower percentiles mean fewer interventions and often lower insurance costs.

BASIC Categories, Intervention Thresholds, and What They Reveal About Risk

Intervention thresholds matter. Unsafe Driving, Crash Indicator, and HOS Compliance typically trigger action around the 65% mark. Other BASICs often see intervention near 80%, while hazardous materials and passenger carriers have separate thresholds (60% and 50%).

CSA metrics quantify motor carrier safety and let stakeholders compare commercial motor performance across peers.

- Percentile shifts show whether a company improved or ignored persistent safety deficiencies.

- Discovery often targets SMS snapshots, inspection reports, and investigation outcomes to map a carrier’s compliance trajectory before an incident.

- Plaintiffs use repeated BASIC alerts to argue foreseeable risk; defenders stress corrective action and improving trends.

For more on how enforcement records and expert testimony strengthen liability claims, see Expert Witnesses in Semi‑Truck Accident Claims.

Why Federal Trucking Regulations Matter in Semi‑Truck Accident Claims

Nationwide safety baselines give lawyers measurable proof to link driver or company conduct to crash outcomes. The federal trucking regulations and FMCSR standards create the objective evidence courts rely on: HOS and ELD logs, CDL and medical files, Clearinghouse entries, DVIRs, and maintenance work orders.

When those records are complete and accurate, they can shorten disputes and focus cases on causation and damages. Carriers that prioritize compliance, weight control, securement, and drug and alcohol testing reduce exposure, while those that cut corners often face heightened liability.

For victims and families, understanding these rules is more than technical detail — it’s the foundation for proving negligence and securing fair compensation. Federal standards provide the roadmap for attorneys to reconstruct events, challenge company practices, and demonstrate how violations directly contributed to harm.

Ultimately, these regulations are not just bureaucratic requirements; they are life‑saving safeguards. When carriers comply, they protect communities and reduce risk. When they fail, the same records become powerful evidence in court. For further guidance on how these benchmarks affect claims, review Federal Trucking Laws That Impact Semi‑Truck Accident Claims.

Frequently Asked Questions on How Federal Trucking Regulations Affect Semi‑Truck Accident Cases

How do FMCSA rules shape liability in semi‑truck accident cases?

The Federal Motor Carrier Safety Administration sets safety standards that courts and juries use to assess liability. When a carrier or driver breaks a rule — such as hours‑of‑service or maintenance requirements — that breach can establish negligence or negligence per se in semi‑truck accident litigation.

Who must follow the FMCSR, and how does coverage affect semi‑truck accident claims?

The FMCSR apply to employers and drivers engaged in interstate commerce operating commercial motor vehicles over 10,001 pounds, passenger vehicles with certain seating thresholds, or hazardous materials carriers. This broad coverage ensures that both small operators and large fleets are accountable in semi‑truck accident cases.

How do hours‑of‑service limits help prove driver fatigue in semi‑truck accident claims?

The 11‑hour driving limit, 14‑hour duty window, mandatory breaks, and weekly caps provide objective benchmarks. Violations documented by logs or ELDs create strong evidence of fatigue, which attorneys use to establish fault and foreseeability in semi‑truck accident cases.

How can electronic logging device (ELD) records be challenged in semi‑truck accident litigation?

ELD data is generally admissible but may face disputes over integrity, tampering, or malfunction. Preservation of raw files and expert analysis are critical to authenticate logs and rebut claims of spoliation in semi‑truck accident cases.

Which driver qualification documents matter most in semi‑truck accident claims?

Key items include the CDL, medical examiner’s certificate, driver qualification file, motor vehicle records, and hiring paperwork. Missing or falsified entries can demonstrate negligent hiring or supervision, strengthening liability arguments in semi‑truck accident cases.

How do drug and alcohol testing rules affect semi‑truck accident investigations?

Mandatory post‑accident testing, random programs, and Clearinghouse records can reveal impairment or prior violations. A positive test or missed test strengthens liability and regulatory exposure in semi‑truck accident claims.

How do maintenance records prove mechanical negligence in semi‑truck accident cases?

DVIRs, repair orders, maintenance logs, and annual inspection certificates are central. Missing or altered records often indicate spoliation or poor safety culture, helping plaintiffs show negligent vehicle upkeep in semi‑truck accident litigation.

How do inspection and out‑of‑service orders influence semi‑truck accident liability?

Out‑of‑service orders and inspection violations are strong evidence of known mechanical defects or unsafe practices. Courts often treat them as proof of actual notice and foreseeable risk in semi‑truck accident cases.

What regulatory violations most often appear in semi‑truck accident litigation?

Common violations include hours‑of‑service breaches, poor maintenance, improper cargo securement, overweight loads, driver qualification lapses, and drug/alcohol compliance failures. Each can independently support negligence claims in semi‑truck accident lawsuits.

How does cargo securement law connect to semi‑truck accident causation?

Improper tie‑downs or unsecured loads can cause rollovers, debris collisions, or loss of control. Evidence of noncompliant securement practices directly links carrier conduct to crash mechanics in semi‑truck accident cases.

What special rules apply to hazardous materials carriers in semi‑truck accident claims?

Hazmat carriers must follow strict registration, labeling, training, and emergency response requirements. Violations increase liability and damages when hazardous shipments worsen injuries or environmental harm in semi‑truck accidents.

How do gross vehicle weight and axle limits affect semi‑truck accident safety findings?

Exceeding weight limits reduces braking, steering, and stability. Scale tickets and logbooks showing overloaded runs are used to prove reduced safety margins and causation in semi‑truck accident cases.

Why do CSA scores matter in semi‑truck accident litigation?

CSA scores summarize a carrier’s safety performance across BASIC categories. High or worsening scores reveal systemic safety problems and can persuade juries about negligent practices in semi‑truck accident cases.

How should evidence be preserved after a semi‑truck accident?

Parties should issue immediate preservation notices for ELD data, dispatch records, DVIRs, maintenance files, and driver logs. Early forensic collection prevents spoliation and ensures evidence remains available for semi‑truck accident litigation.

Can employers be held vicariously liable for drivers in semi‑truck accident cases?

Yes. Employers face vicarious liability under respondeat superior for actions within the scope of employment. Negligent hiring, supervision, or maintenance can further increase liability in semi‑truck accident claims.

What penalties can FMCSA impose after semi‑truck accident violations?

FMCSA can issue fines, out‑of‑service orders, compliance reviews, and even carrier shutdowns. Severe violations tied to semi‑truck accidents may lead to civil penalties or criminal enforcement.

How do state laws interact with federal standards in semi‑truck accident claims?

State tort law governs liability and damages, while federal safety standards provide compliance benchmarks. Federal preemption may apply when conflicts arise, but state law often fills gaps in semi‑truck accident remedies.

What steps should plaintiffs take to build a strong regulatory‑based semi‑truck accident case?

Plaintiffs should secure ELD data, DVIRs, maintenance records, driver qualification files, drug/alcohol test results, and CSA history. Expert witnesses help translate regulatory breaches into causation and damages in semi‑truck accident litigation.

Disclaimer: The information provided in this article is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the content, laws and regulations may vary by state, and individual cases may have unique circumstances. For advice tailored to your specific situation, please consult a qualified attorney. The inclusion of links to external resources does not imply endorsement or guarantee of the information provided therein.

Related Articles

- Punitive Damages in Semi-Truck Accident Cases: When Are They Awarded?

- The Differences Between Trucking Accidents and Regular Car Accidents

- Navigating Multi-Party Lawsuits in Semi-Truck Accidents

- Insurance Company Tactics to Watch Out for in Trucking Accident Cases

- Who Can Be Held Responsible in a Semi-Truck Accident Case?

More from This Category

- How to Prove Negligence in Semi-Truck Accident Lawsuits

- What You Need to Know About the Statute of Limitations for Truck Accident Cases

- Top Reasons Semi-Truck Accident Claims Are Denied and How to Fight Back

- The Importance of Evidence in Semi-Truck Accident Claims: Building a Strong Case

- How Comparative Fault Affects Semi-Truck Accident Settlements and Compensation

Additional Resources

- Understanding Vicarious Liability in Trucking Accidents

- How Federal Trucking Regulations Impact Your Semi-Truck Accident Case

- FAQs for Semi-Truck Accident Victims: Answers to Your Most Pressing Questions